Lean Manufacturing

What is 5S Method: A Powerful System for Boosting Workplace Efficiency and Organization

5S is a method designed to improve organization and efficiency in the workplace. It originated in Japan and was made ...

Just in Time (JIT): Definition, Origins, Benefits, and Toyota’s Success

Just in Time (JIT) is an approach used to increase efficiency and reduce costs in production processes. This system minimizes ...

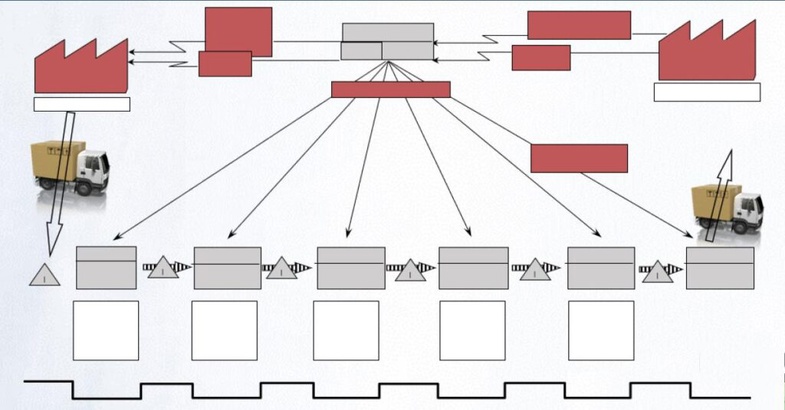

What is Value Stream Mapping (VSM)? Symbols, Tools and Examples

Product development resembles a maze. The destination is known to have an output, but the journey is uncertain. Value Stream ...

What is Kaizen (Continuous Improvement)? Definition, Process and Examples

Kaizen, one of the foundations of the Japanese quality of work and personal life, is the most well-known continuous improvement ...

What is Six Sigma? Definition, Methodology and Techniques (Comprehensive Guide)

The Six Sigma concept is a statistical indicator that measures the extent to which a process deviates from perfection. When ...

What is Lean Manufacturing? Principles, Techniques, and 7 Wastes!

Lean manufacturing is one of the cornerstones of modern industry. Basically, it is a name given to efforts to minimize ...