Production scheduling is a critical process for modern industrial enterprises to improve efficiency and gain competitive advantage. In this article, we will provide an in-depth introduction to production scheduling. In the following sections, we will cover important topics such as the importance of production scheduling, methods, steps, and examples.

We will also include valuable information on how to optimize production scheduling. Our article aims to explain to the readers the importance of the production scheduling process and emphasize the importance of expertise, experience, and competence in this field. If you are ready, let’s start our article.

Contents

What is Production Scheduling?

Production scheduling is the short-term production program designed for the implementation or realization of the main production schedule. It is a planning activity that tries to find out how best to use the available capacity, taking into account technical production constraints. Production scheduling is a common programming (scheduling) problem where multiple jobs are processed at one or more workstations. If careful scheduling is not done, bottlenecks and waiting (queuing) lines are inevitable.

Production scheduling plays a crucial role in speeding up the delivery of products to customers and the market. It forms an integral part of the broader manufacturing supply chain, encompassing various aspects such as raw material procurement, labor, logistics, costs, and production timelines.

Before starting the production process, companies should address production scheduling. This step is crucial as it determines the costs associated with production and labor and requires the allocation of financial resources for each stage of the production cycle.

It is imperative to determine the optimal timing to bring the product to market. Striking a balance between speed and quality is key and often requires a backward approach from a specific deadline. This involves understanding the production lead time and the timeline for the transportation of finished products to distributors, thereby balancing resources for timely access to required components.

Production Scheduling vs. Production Planning

Production scheduling and production planning are interrelated yet distinct processes. Depending on the nature of production, a manufacturer may opt for one over the other.

It’s crucial to grasp the disparities between them. Production planning offers a broad perspective on product timelines, whereas a production schedule delves into finer details of the manufacturing process.

The Importance of Production Scheduling

Effective production scheduling is integral to manufacturing, optimizing production timelines, reducing costs and shortages, and minimizing interruptions, delays, and waste.

Moreover, production scheduling encompasses the following eight elements:

- Parts Distribution: By allocating the appropriate types and quantities of parts to workers at various stages of production, schedules mitigate bottlenecks and waste.

- Stock Levels: Scheduling ensures optimal stock levels. Facilitates warehouse organization, and enables accurate tracking of outputs.

- Allocation of Labor: Utilizing a production schedule enables accurate tracking and management of working hours, overtime, and necessary workforce levels per shift or production cycle.

- Equipment Efficiency: Through equipment evaluation and scheduling, manufacturers can enhance the utilization of workstations and machinery, minimizing the requirement for additional purchases or excessive equipment usage.

- Financial Management: Scheduling aids in resource allocation, enhancing efficiency and reducing financial risks, thereby improving the reliability of available funds and mitigating financial crises.

- Enhanced Product Quality: Well-designed production schedules contribute to improved product quality within tighter timeframes.

- Strengthened Customer Relationships: Timely fulfillment of customer orders facilitated by production schedules fosters satisfaction, trust, and brand loyalty.

- Positive Company Reputation: Enterprises that optimize manufacturing schedules are recognized for their punctuality, cost-effectiveness, and commitment to both employee welfare and customer satisfaction.

Six Production Scheduling Steps

Crafting a production schedule demands a delicate equilibrium between the demands of clientele and the temporal and material resources at your organization’s disposal. Regardless of whether you’re engaged in product development or software projects, your schedule must include phases for planning, routing, scheduling, dispatching, executing, and maintaining.

Let’s delve into these six steps further:

1) Planning

In the initial phase, a company conducts planning of resources, budgets, staffing, inventory, and timelines to appraise the state of production processes. There are two primary planning methodologies to consider:

- Static Planning: This approach operates under the assumption that no alterations will occur throughout the production process.

- Dynamic Planning: Unlike static planning, dynamic planning anticipates potential changes that may arise during production.

During this stage, it’s crucial to establish strategic objectives and determine labor and capacity requirements.

2) Routing

During the routing phase, a company maps out the journey that raw materials must traverse from their initial state to the final product. This process entails identifying the most efficient and economical steps within the manufacturing procedures.

3) Scheduling

During this phase, precise dates and timings for a project are formally established utilizing the company’s designated methodology. Various types of schedules can be generated, comprising:

- Master Schedules: Comprehensive, high-level schedules encompassing breakdowns for labor, routing, resources, and other essential elements.

- Manufacturing Schedules: These schedules are more focused, detailing only the necessary routing steps within the manufacturing process.

- Retail Operations Schedules: Specifically tailored for retail operations, these schedules incorporate routing steps pertinent to both traditional retail and e-commerce products.

4) Dispatching

Dispatching involves issuing directives regarding the whereabouts of individuals, components, and goods. During this phase, the company delineates the methods by which these entities will be transported to their assigned destinations throughout the scheduling continuum.

5) Executing

This phase entails the actual implementation of the production schedule from inception to conclusion, marking the pivotal moment of success or failure for the company. A meticulously researched and formulated schedule should facilitate a seamless production process.

6) Maintaining

Following the implementation of the production schedule, a two-way communication channel opens between management and employees. This phase serves as a platform for identifying areas necessitating enhancement, empowering the company to enact proactive measures accordingly.

Production Scheduling Methods

In the production scheduling process, companies can optimize their systems using various methods, despite the standard six steps. Capacity planning and forward and backward scheduling emerge as the predominant approaches for crafting production schedules.

Capacity Planning

For companies prioritizing client satisfaction, capacity planning stands out as a primary scheduling approach. Capacity planning focuses predominantly on resource availability, service delivery, and ensuring customer satisfaction.

Capacity planning encompasses two primary types:

- Infinite Capacity: This approach operates under the assumption of unlimited resources, including workers, workstations, parts, and inventory.

- Finite Capacity: This method acknowledges predefined limitations such as working hours, resource availability, equipment, labor, and other relevant factors.

Companies managing several large, concurrent projects may find infinite capacity planning suitable, whereas those dealing with numerous complex projects simultaneously are better suited for finite capacity planning.

Forward and Backward Scheduling

Forward and backward scheduling offer alternative approaches for establishing a project’s production sequence. These methods rely on either the initial step or the deadline to define the project timeline, outlined as follows:

- Forward Scheduling: This technique involves setting the timeline starting from the earliest step and sequentially scheduling subsequent tasks.

- Backward Scheduling: Conversely, this method constructs the project timeline starting from the due date and progresses backward.

Backward scheduling, also termed a workback schedule, proves most effective for projects with rigid deadlines. When employing forward and backward scheduling, it’s essential to ascertain whether your project hinges on specific due dates or tight schedules.

How to Optimize Production Scheduling?

In production scheduling, where methodologies, contributors, and various factors play pivotal roles, it becomes imperative to continuously refine and optimize processes. A highly effective approach towards achieving this optimization entails the integration of agile planning methodologies into the scheduling framework.

Incorporating agile planning involves several key considerations:

- Dynamic Scheduling: Anticipate and accommodate fluctuations in distribution, resource allocation, labor utilization, workforce capacity, and other pertinent variables by crafting a schedule that is flexible and adaptable.

- Work-in-Progress Control: Establish a prioritized schedule and categorize projects based on their level of importance. This ensures that critical and time-sensitive projects receive the necessary attention and resources to stay on course.

- Prioritized On-Time Deliveries: In prioritized production scheduling, it’s essential to prioritize on-time deliveries based on needs and resources rather than just the due date.

- Inventory and Supply Management: Efficient management of inventory and supplies involves coordinating the arrival and availability of resources to minimize product loss or operational disruptions.

- Maintained Equipment and Facility: Ensuring the upkeep of equipment and facilities is crucial for maintaining production timelines and safeguarding the well-being of workers.

- Production Scheduling Software: Leveraging production scheduling software facilitates the efficient management of orders, inventory tracking, labor organization, and other essential tasks, thereby enhancing productivity and operational effectiveness.

Production Scheduling Example

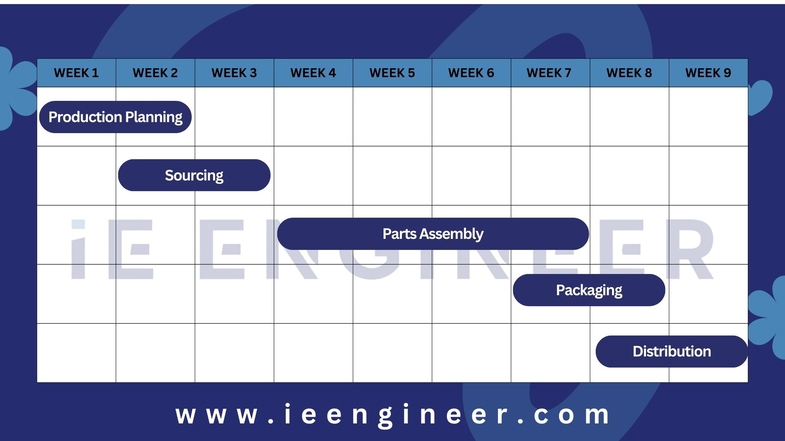

Let’s illustrate the entire process of a product from the planning stage to the distribution stage through a simple production scheduling example.

In the example below, we see that a product has a planning process in the first two weeks. Starting from the second week, we carry out the sourcing and planning phase together. Between the fourth and seventh week, our product is produced. We package the products produced so far in the last week of the production phase. Packaging time is planned as 2 weeks. In the eighth week, we carry out the packaging and distribution process together. In the last week, the ninth week, we only distributed the products.

This production scheduling example is simple. Different examples can be made with different stages.

What is Production Scheduling Software?

Utilizing production scheduling software provides a centralized platform for crafting, organizing, and overseeing your production schedule seamlessly. Referred to as Advanced Planning and Scheduling (APS) software, this technology empowers you to generate dynamic and current schedules that span various teams effectively.

We will prepare detailed content about the best production scheduling software. But if we need to present a short list; according to the comments made, the best production scheduling software is as follows;

- ClickUp

- MasterControl

- Odoo

- NetSuite

- MRPeasy

- Visual Planning

- Schedlyzer

- Optessa

- Katana MRP

- InkSoft

As mentioned above, we will prepare detailed content about the best production scheduling software. Do not forget to visit our website to be informed about our article.

Videos Related to Production Scheduling

We would like to suggest you a video about production scheduling. You can learn about production scheduling by watching this video. You can click HERE for more videos.